Description

Custom Made Badges & Name Tags – made to order

(including Custom Metal Badges and Custom Rubber Badges)

Custom made badges from QW Direct are designed to be the best in town and last a life time.

Using only the most advanced metal moulding and finishing processes, our custom badges have to be seen to be believed!

We are flexible to work within your custom design & sizing.

In most cases just confirm your logo (or photo of existing design) and dimensions, and we will recommend the best design package to suit your requirements. If you want to have more understanding and creative direction into your design, you are welcome to learn all the finer details so you can to steer us in the direction you want your design to follow….the choice is yours!

Custom Badges – available materials

- hard enamel

- imitation hard enamel

- die struck soft enamel

- photo etched soft enamel

- die struck copper or brass without colours

- iron soft enamel

- silk screen printing or offset printing

- pewter or zinc alloy

- soft PVC with 2D (flat) or 3D (risen from surface) logo

Custom Made Badges – available attachments

- Spur nail & butterfly clutch

- Magnet

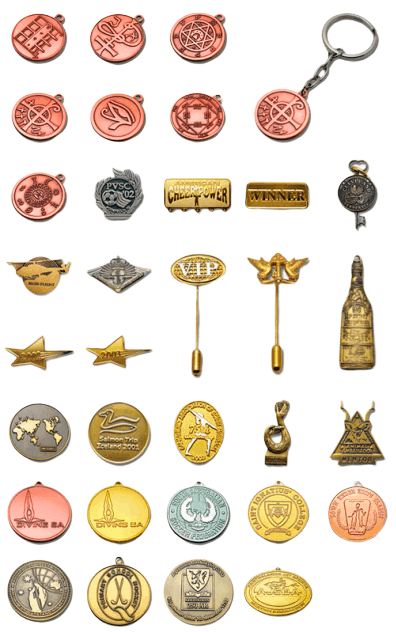

Custom Metal Badges

These have been very popular for professional staff attire, corporate uniforms, University students and school groups.

Custom Metal Badges – available materials

- copper

- bronze

- iron

- zinc alloy

- pewter

- aluminium

- stainless steel

Standard Size: 1/2 ~ 2″ or any other size can be requested.

Standard Thickness: 0.8 ~ 1.6″ or any other thickness can be requested.

Custom Metal Made Badges – available finishes

- Nickel

- Chrome

- Silver

- Gold

- Matte

- Satin

- Antique

To understand our metal plating options further please [CLICK_HERE]

CMB-082

CMB-090

CMB-088

CMB-030

CMB-031

CMB-033

CMB-035

CMB-041

CMB-59

CMB-061

CMB-040

CMB-732

Custom Rubber Badges

Custom Rubber Badges (also known as soft PVC badges) are also popular as this design option allows for refreshingly bright colours. It provides a soft appeal experience, and it is generally very cost effective option.

CMB-024

CMB-077

CMB-083

Various available Metal Moulding & Finishing Processes

Hard Enamel

Hard Enamel (also known as Cloisonne) originated thousands of years ago, as was originally used to decorate vases.

Hard Enamel consists of a powder of glass like mixture. Each colour is hand filled with a tiny spoon onto the copper recess area stamped by a die. After fusion, it resists scratching by knife or even heating to 800 degrees. It is renowned for its jewellery like finish, immortality and limited natural supply, making it an ideal method in the production of clothing emblems, custom badges and various collectible memorabilia.

For each colour ordered, a custom metal badge in this material has to undergo one time direct heating over 1700F (900°C+) before the powder can melt and be crystallised. For example, if there are 4 colours, the same badge has to undergo 4 baking processes of one colour after the other.

Features

Preservable for over 100 years with ceramic-likened glaze resistant to scratch, heat, humidity & acidic chemicals (however limited in choice of colours)

Matching metal: is copper which is capable to endure similar high temperature but curved a little after baking.

Imitation Enamel

Imitation Enamel is similar in production to traditional cloisonne (Hard Enamel) except that a special resin is utilised to provide colours instead of the natural cloisonne colour. Colours can be matched to Pantone Colours in this type of custom badge. The design is die stamped out copper pieces, in a true cloisonne badge design.

Imitation Enamel was only invented in 1985 to meet the overwhelming demand for hard enamel. The synthetic pigments give a gorgeous appearance which is very close to Hard enamel, but more shiny. The prime advantage of Imitation Enamel is the ability to specifically choose colours according to the PMS (Pantone®) colour chart.

Features

- 90% correlation and appearance to hard enamel.

- non-resistant to scratch nor heat over 212F(100°C).

- More shiny, colourful and smooth than Hard Enamel.

Matching Metal: Copper

Soft Enamel

This represents one of the most popular and cost effective production processes, especially when finishing on Iron.

The colour is a rich PMS base, which delivers a brilliant shine on copper, iron & aluminium – through a process of stamping or photo etching.

Soft Enamel Stamped Copper / Brass

Soft Enamel Copper uses paint pigments similar to those applied on a car, representing a more cost effective option than hard or imitation enamel.

This process only requires 100°C degree to dry the paints during a 4 – 5 minute oven heat. The unique raised rims render a refreshing metallic experience, giving years of treasured ownership to the customer.

Designs that need a thin border or outline are perfect to apply soft enamel to.

Similar to Imitation Enamel, however:

- Plating takes place before colouring to speed up the process.

- A fabric wheel is used in polishing.

- Epoxy may be added, depending on order requirement.

Features

Shiny and smooth in surface, but vulnerable to scratch and high temperatures

Epoxy (a thin layer of transparent plastic) is often applied to protect the badges from scratching. The paint is thinner than Hard/Imitation Enamel and lower than the raised metal rim. Colour choices are available according to the Pantone number (PMS).

Matching Metal: Copper (1.2mm+), Brass(0.8mm+), Iron(0.8mm+), Aluminium(0.8mm+), Stainless Steel.

Stamped Iron Soft Enamel

With Soft Enamel Stamped Iron, these custom badges are very similar in production to the soft enamel, except that the material used is iron instead of copper. Pantone colours are used and can be chosen for these types of custom metal badges. These forms one of the lowest cost processing options of all the different types of custom badges available today. The surface of an iron metal badge may be covered with epoxy to protect the colours.

Photo Etched Soft Enamel

Soft Enamel Photo Etched uses photographic negative techniques to produce these type of badges. The negatives are made to the exact size of the design and laid out across the surface of the copper metal, which is then dipped into a chemical solution to etch the image into the metal – at which stage colour can be added. The colours are applied to all etched areas before the metal is placed into the oven. A clear epoxy coating can be added to protect the soft enamel colours.

Soft Enamel Stamped without Colouring

With these high-polished custom badges, they do not have their recesses filled with enamel paints. Instead the recesses of these crafted pins are finished with sandblasting or a foggy process to achieve a “brushed” effect. Then the raised areas are highly polished for a very shiny presentation.

Stamping without colour means the colouring is undertaken by electro-plating instead of enamel or paint.

Plating Options

Gold – Silver – Nickel – Chrome – Black Nickel – Copper – Black Dye in either shiny antique or 2-tone finishes –

Foggy – Sandblasted – Granulation

This design provides a genuine taste of metal by metallic colour & heavy weight. This is most commonly applied to coins, medals, pins & badges.

Matching Metal: Copper(1.2mm+)

Custom Badges – with printed logos

Silk Screen and Offset printed custom badges allow for special logos and designs to be used, without the need for fine gold or silver plating around each colour. Colours are silk screened onto a bass material one by one at each time, just like creating a T-shirt. A final clear epoxy coating should be added to protect the colours.

With industrial strength capabilities and host of design options, we look forward to producing your order!